Our virtual meeting this month had the snappy theme "Uses, Misuses, Advantages, Disadvantages and Frustrations in the use of DCC". Nigel, Jim, James, Stephen, Chris G, all three Al(i/a)s(d/t)airs, Graham, Simon and visitor Andrew participated. Most are already using DCC, or planning to use it, so there was plenty experience on tap and the discussion was wide-ranging. Some noteworthy points:

- retrofitting DCC to small prototypes is difficult, it's much easier to plan it in the design phase.

- DCC doesn't eliminate the need to clean track! (and Roco track rubbers are much preferable to Peco, since they don't crumble)

- it's important to try a few controllers to discover your personal preference before deciding which to buy, because there is no consensus on whether rotary, push-button, or variations on these themes are best for speed and direction control.

- Although a home-brew DCC controller based on an Arduino or similar board can cost as little as £30, the best starting point for many is a capable but extendable main unit from Zephyr or Digitrax in the £170-£200 bracket.

- The Railcom system (allowing controlled entities to talk back to the controller) comes into its own on club layouts since it allows locos to inform the controller of their details, reducing confusion when other peoples' models are being operated

- a SPROG (dedicated hardware allowing programming via a graphical user interface on a PC/laptop/tablet) is much more convenient than programming via a DCC controller

- for locos which do a lot of shunting as well as hauling trains, it can be helpful to set up a "yard mode" with finer control and firmer braking as well as the normal traffic settings

- "power districts" (subdivision of the layout into sections, with individual switched power feeds which can be isolated) are recommended to ease fault-finding, since they allow a short-circuit to be localised much more quickly

- coupling designs requiring a "shuffle" to uncouple can have the shuffle action programmed into a single key, where the DCC chip supports it (typically European designs)

We spent a couple of hours talking through all that. There were a couple of progress reports from individual layouts. Chris G showed us how trackwork, earthworks and structures are progressing on Bosalek:

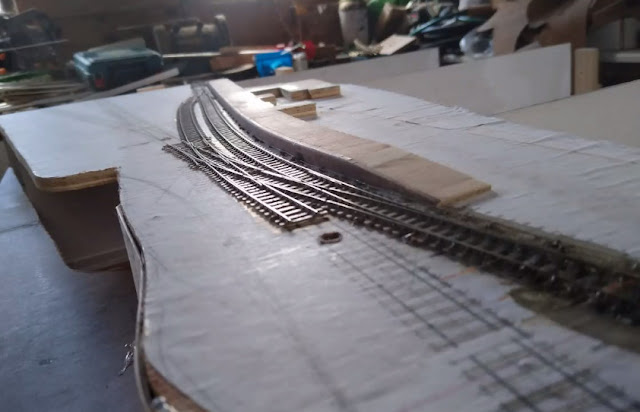

Simon is at a similar stage with Glenfinnan:

He is less happy with the running gear for his observation saloon: the 3D-printed body does not make sufficient allowance for the wheels and rides too high: some excavation will be required. However, it's progressing.

Although we expect to have at least one more virtual meeting (on 8 May), we are daring to hope that a physical meeting may be possible, no doubt with masks, distancing and so on, in June.

No comments:

Post a Comment