Alisdair, Alistair, Andy, Jim, Stephen Harold, Stephen Hawkins, Phil and Graham met at Chris's house in Edinburgh for our February get-together. In a slight change of format, Alisdair had sent out homework ahead of the meeting: everyone was enjoined to bring a current project or other talking-point with them as the basis for each to give a five-minute talk. Of course the inevitable happened and each five minutes turned into 20, so that we broke for lunch before we'd got through listening to even half of the presentations. Never mind, it was all good stuff, and there will be plenty material for a future meeting.

First up was Andy, who passed round the photos and plans he's collected for his chosen prototype, Aberdour station in Fife. He reckons he can get it into an 8-foot viewing section without any compression. It's an attractive prototype, a station on a slight reverse curve with convenient overbridges at each end and a 11th-century ruined castle to one side. Maybe 2019 will be the year the model comes to life.

Discussion centred on whether it would be better to straighten the station out to simplify turnout construction. The consensus was that, provided that turnouts were built methodically, with each stage in the proper order, and not moving to a subsequent stage before being 100% satisfied with the previous one, as well as ensuring closure rails lined up with the crossing vees correctly, there was no reason not to build curved turnouts using a Templot plan.

Next to take the floor was Phil, who brought an ecumenical note to the meeting by talking about N gauge Finetrax points. He is in the process of building 46 of these as a customer order. He showed us the sintered crossing castings which look very neat. The moulded plastic base and chairs are from the same stable as the Easitrac parts familiar to 2mmSA members. Phil mentioned that it's easy to inadvertently snap the moulded chairs when trying to separate them from their sprues after threading them onto rail. He finds that very fine cutters specifically designed for sprue separation is the best solution - Xuron track cutters are too coarse - he uses Micromark cutters, I would guess these ones, although Micromark list a wide and tempting range of other cutters on their website. One of the challenges with Finetrax is attaching the operating mechanism to the tiebars, which are now of plain rather than copperclad glass-fibre strip, so that soldering a pin to the tiebar is not possible. Phil's customer only has 30mm depth below the baseboard, adding to the challenge of designing an effective operating mechanism. However, he appeared undaunted.

There was some discussion whether it still makes sense to adopt 2FS 1:152, 9.42mm gauge standards for a prototype which can be modelled with commercial 1:148, 9mm British N gauge rolling stock. Modern N wheel profiles are close to 2FS and the rail profile is the same, code 40 bullhead. A gauge slightly narrower than scale and slightly-wider flangeways are perhaps compromises worth making in the interests of finishing a layout more quickly.

Steve Harold showed us a couple of (2FS!) locos he built some time ago from Fencehouses etched kits. A J72 in BR livery:

and a project still in progress, an ex-NER Q5 0-8-0 freight loco:

The Q5's weight is in a separate tube within the boiler so it could be moved to balance the loco correctly before being fixed in place. Steve's very neat soldering was remarked upon: the result, he told us, of using 145°C melting-point solder, which "wets" the metal better than 188°C due to lower surface tension. He uses the 188°C stuff when necessary for stronger joints or to ensure bits don't fall off. Phil revealed he prefers to silver-solder frames so they don't come to bits, holding the parts together with modified wooden clothes pegs, placing small shavings of solder on the joint, and using a microflame torch to fuse the solder.

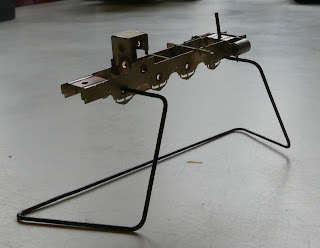

Another point of interest was Stephen's simple but effective frame to allow spray painting of a chassis, simply bent up from stiff wire.

Jim took us through the design process of his current project, a lattice footbridge for the Grampian group's Dunallander project started by the late Neil Ballantine. The footbridge, the second one at the north end of Dunblane station, replaced a standard Caledonian Railway wooden design and probably dated from the 1920s (it was removed in the 1970s). The original plans have not been uncovered, so Jim's design is based on the few available photos and a knowledge of Caley lattice bridge practice elsewhere, as well as detailed measurements of the site it has to fit on the layout. Not at all a simple matter, as he explained with the help of his laptop and Autocad.

That was the end of the talks, since it was lunchtime. Chris served up his home-made soup and large stacks of bacon rolls. After lunch, we made a concerted effort to re-gauge and generally renovate Sauchenford's fiddle yard cassettes, made from aluminium angle "rails" screwed to a plywood strip base with styrene-sheet side walls. The decision to use small woodscrews to attach the angle to the ply was in retrospect a mistake, since they have not held their positions tightly enough and are forever going out of gauge after handling. The angles were carefully gauged and glued in place this time. We will see whether this works better in the long term.

Before we finished up, Alisdair's Caley Jumbo (294 class) was given a quick airing. He recently drop-tested the model, chipping the chimney, but he gave it a quick swipe with a file and it seems little the worse. It looks quite the part of a loco at the end of its service life, with replacement lum (chimney), dome cover and safety-valves, wearing a class K (branch freight or ballast train) lamp to signify how far down the pecking-order it has fallen. (The chromed bull-bar sported on its buffer-beam is in fact an Electra coupling hook).

Shortly before we finished up, Chris gave us a quick demo of his low-cost DCC system, based on an Arduino microcontroller with a Motorshield board to drive a 15V supply to the track. Just over £40 for these two, or half that if Chinese copies are used. Free open-source JMRI software is used to control the Arduino with Engine Driver software allowing a mobile phone to be used in place of a PC. Chris demo'd this working with his 4F, a design with enough space to hide the Zemo 622N chip (another £20) which Nigel Cliffe had recommended to him as a good option to dip a low-cost toe in the DCC water. The loco's controllability on his test track was most impressive - proof that DCC does not have to cost a fortune and that a low-cost trial is very feasible if you are curious to see if it suits you.

The next group meeting will hopefully consist of a visit to the EM/S4 societies' Skills Day in Linlithgow in March to find out how things are done when you can actually see what you're modelling ... We will re-convene in Glasgow in April. Thanks Chris for top-class catering, and for tolerating our invasion of your household.