Saturday was the monthly meeting of the Forth and Clyde Area Group, where eight brave souls ventured out in soul melting heat to model the railways of yesteryear in the Finest of Scales (see what I did there?) Alastair, Alistair, Jim, James, Nigel, Stuart, Graham and Martin were in attendance this month.

There were two distinct themes to this months meeting, with the modelling projects falling nicely into two discrete categories, the Group Layout and locomotive works, with only minor diversions along the way.

Work continued on the Group Layout. Jim had been beavering away at home continuing the wiring and testing with his fleet of Caledonian Railways locomotives, some of which were on show. However, it was pointed out that there had almost certainly been no diesel traction gracing the irons. Well, Nickle/Silvers. And so, several of these locomotives, from Class 26, to Class 37 to Class 121 were ran through the various turnouts in various orders to check gauging and movement - with Jim's admonition that "Coughs and Sneezes Spread Diseasels" ringing in our ears.

This did throw up a couple of issues running under DC which were rectified in short order by Jim and Nigel, and before lunchtime, all of the roads and turnouts had been tested under the wheels of several diesels, and one or two of Jim's CR locomotives.

This work also threw up a couple of running issues with Martin's Class 26 and 37 - the 26 wasn't running at all under DC, and the 37 was making an awful noise - and no, not the agricultural sound of the engine for Martin has not fitted the loco for DCC Sound (yet) - something was clicking in the mechanisms, somewhere. Confessing a lack of knowledge in how to remedy either of these issues, Nigel stepped in to inspect the issues and help remedy them, resolving the issues through careful inspection and fault finding.

The Caledonian Railway "Jumbo", resplendent in the "goods black" livery of the Caley, one of Jim's newer constructs, from his own etches.

Another of Jim's vast loco fleet, this time CR No.29, the flagship of the 29 Class, equipped with condensing apparatus to allow working underground through the Caledonian Railway routes under the city of Glasgow.

On the subject of the Group Layout - Alistair had constructed a miniature mock-up of the layout to aid in understanding how the backscene would go together. He continued looking at various books and photos for inspiration, a plan appears to be coming together.

Nigel and Jim discussed the "fiddle stick", the exterior attachment to the layout to allow stock to enter and leave the scene without the hand of god, or at least a 2FS modeller, reaching in and out at random. Jim had prepared a sketch, which he and Nigel discussed and debated. The hole to the real world was cut into the side panel too, with a couple of locos used to test clearances.

Graham, in his first of two entries this month, had brought along some 3d test prints of the engine shed which will be the primary focal point of the layout. Based on the design of Forfar, he had been testing brick spacing and course depth to create the optimal structure. There was some discussion on painting the brick and mortar, with three strategies suggested:

1. Don't - it's too small to see in 2mm

2. Paint the mortar colour as the basecoat, then drybrush the brick colour over the top.

3. Paint the brick colour first, then varnish. Apply a wash of a very thinned down sand/offwhite oil paint, leave for around an hour, then use a cloth/cotton bud dipped in thinner to wipe the excess of the top surface, leaving the lighter colour in the appropriate places.

Not falling into either of the two well defined categories, was Stuart, who was continuing work on his N Gauge Mill building(s). Last month we saw how he used 1mm clear acrylic to make the main shell of the building, using the white backing paper to create the window detail, and used mountboard to create the outer shell, with windows cut out and brickwork scribed in. This time round he was painting the whole of the mountboard with a grey acrylic paint as a base. He paints both the inner and outer face to prevent warping, and ensures to get the insides of all the windows so none of the card colour shows through. The next step is to use Humbrol weathering powders to create texture and colour more towards the brown of the prototype.

For those who may be new to the Blog, this is the first scratchbuilt building Stuart has ever attempted! "I've got a thirteen arch viaduct to do next" he told us as we looked on in wonder.

On the locomotive building front, four of our members had brought chassis to work on. The idea of the Beginners Locomotive Workshop, being hosted at the end of the month, is for those of us who haven't bult a working chassis, or have to limited success or confidence, to have a go and make a good attempt at getting something running, then use the experience of the tutors to correct any issues and get a clean running chassis. Several of the Group have evidently left the whole "have a go at building a chassis" to the same last minute as this reporter, and were using the session to make a start, or progress.

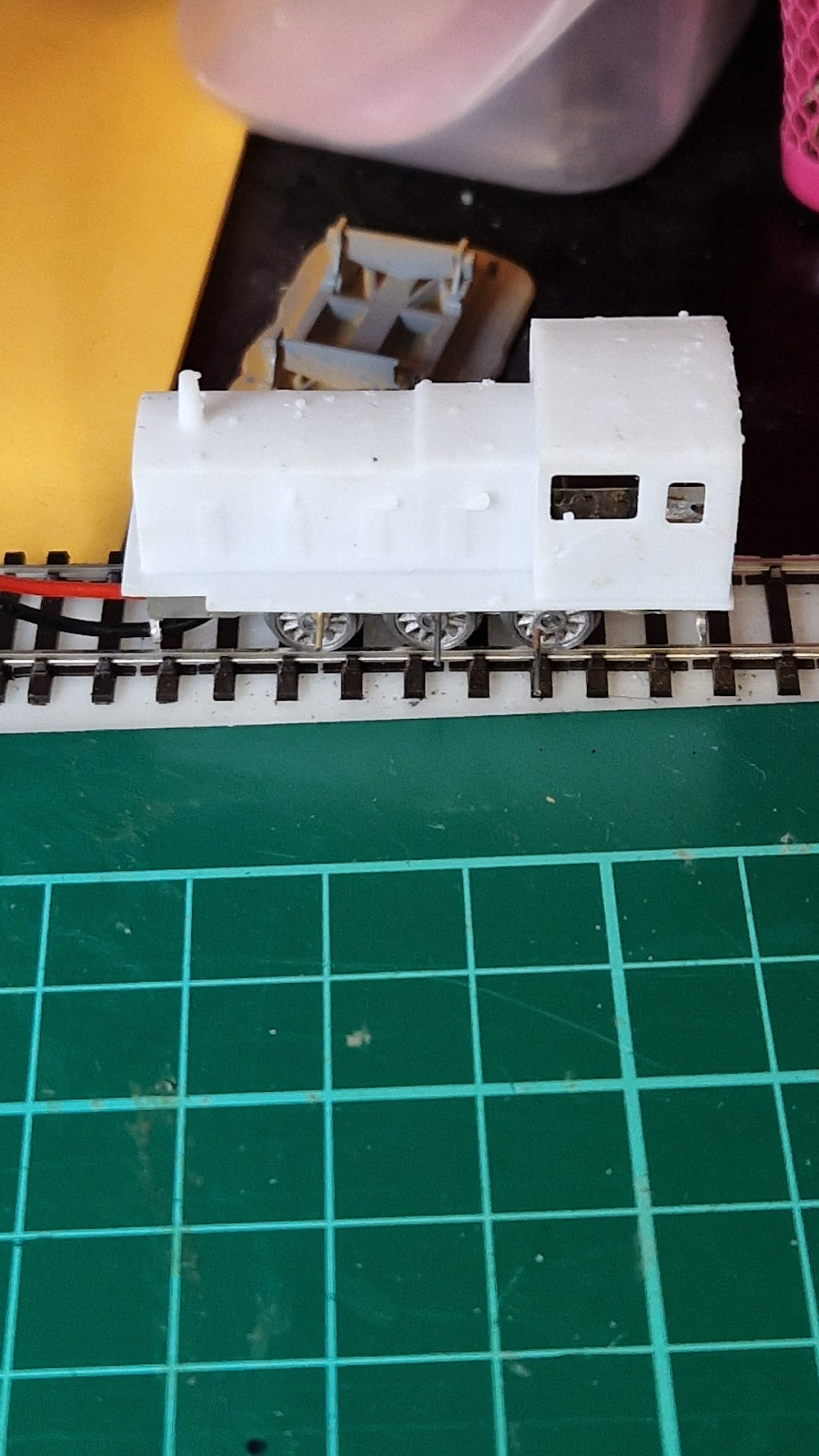

Graham was working on a chassis for a Class 08. He'd opted for the Graham Farish conversion etch and had procured a body in Network SouthEast livery (we really are a broad church...), rather than the Association "kit" which allows one to build both the chassis and the body (see below...). He had the chassis together and square and was proceeding with gearing ready for the beginners locomotive workshop being held at the end of the month.

Alastair was also working on a chassis, this time for a Class 03. Sitting down to start the process of gearing he realised he didn't have any axle steel and was at a loss at what to do, until a kind soul donated a length.

The build progressed at a fair pace with gearing installed by midway through the meeting.

Alastair had also been busy with his 3D printed North British wagons, some now progressing through the paint shop. His next step is detailing and numbering before weathering. Whilst the Association does stock the Modelmaster NBR transfer sheet, Alistair is toying with the idea of 3d printing some stencils to apply the markings in a more prototypical fashion. He was also displaying his first PCB built turnout, now complete and tested.

Martin made a start on his Class 08, between servicing the Diesels, taking photos and joining in with the conversations and discussions, he made it as far as putting the PB bearings into the frames.

This Class 08 the full "kit" from the Association. This differs from the conversion etch in a number of ways (for one, having the cab/body to build and detail oneself), but primarily in the lack of the cantilevered gearbox seen on other etches, with the worm being sat directly on the skew gear using the Associations 3d printed motor mounts, for which there is a flap in the etch with appropriately sized holes for the feet. There is potential for some etching in Martin's future, as a couple of the locomotives he wishes to run either aren't available in N Gauge to convert, or don't have specific conversion etches available and he thought this setup was a very clever idea he may "borrow".

Martin had also brought along his J94 chassis, now running under power on the rolling road. Mostly. He had found that the cantilever gearbox, previously discussed, has a tendency to flex whilst the motor is turning, disengaging the worm from the skew gear and preventing the wheels from turning. This was an issue a couple of the others had seen, and the suggested fix is to solder a sufficiently gapped PCB Sleeper to the open side of the gearbox and the opposite frame to hold everything in place. This may be reported on again at the loco workshop.

James had brought along his chassis to work on, another Class 03, but in setup of his MERG DCC controller and test setup (see last month's blog), a buzzer was sounding which indicated a fault, however, it wasn't clear which fault the buzzer was specifically indicating! so James spent some time fault finding, dissessembling and reassembling his controller.

He'd also brought along his Volt-Wagon. That is not a typo, rather a novel idea for testing track voltage "as the loco might see it". He and another P4 modeller had created one from a proprietry van during the 2020 lockdown, James designing the electronics and his compatriot building the van. James wanted to test whether it was possible in 2mm, and so, using a spare Peco van, he was in the process of installing the electrics to turn it into a voltmeter, on wheels.

The P4 compete model on the right, with the 2FS model under construction on the left

The P4 Model "under test" so as to show how it works. An ingenious idea! This also shows James' home built controller, capable of running DC and DCC to both the test tracks on top, and via a set of leads a whole layout - much of the testing of the Group layout was done using this setup.

And so concludes this month's FCAG meeting. Lots of modelling going on around the room, lots of projects underway.

Our next meeting will be the Locomotive Workshop on 30th September - there are still places available, if you are at all interested in visiting the Central Belt and joining us, details are in the Association Newsletter which accompanied the last magazine.

The next monthly meeting is due to be Saturday 14th October, guests always welcome.